One evening in late 1997, 11-year-old Claire Lackner walked into her dad’s study looking for an idea for an experiment for her sixth-grade science class. Her dad, Klaus Lackner, happened to be a physicist working on nuclear fusion at Los Alamos National Laboratory. He’d grown skeptical that fusion could replace dirty fuels and had started thinking about how to take greenhouse gases out of the atmosphere instead. So he suggested Claire try to capture carbon dioxide from air. She bought an aquarium pump and bubbled air through a test tube of sodium carbonate, a base, which bonded with the acidic CO2 in the airstream, removing about 10 percent of it overnight. Claire won a prize at the county science fair, and her father later wrote a paper arguing that extracting CO2 from air “has a reasonable probability of success” at reducing global warming.

Scientists had known since the 1950s how to strip CO2 from the air inside submarines and spaceships to keep the crews from suffocating. But Lackner’s paper was the first to argue that we could strip it from the atmosphere to keep Spaceship Earth livable. Claire’s experiment, he says, showed “it’s not all that hard.”

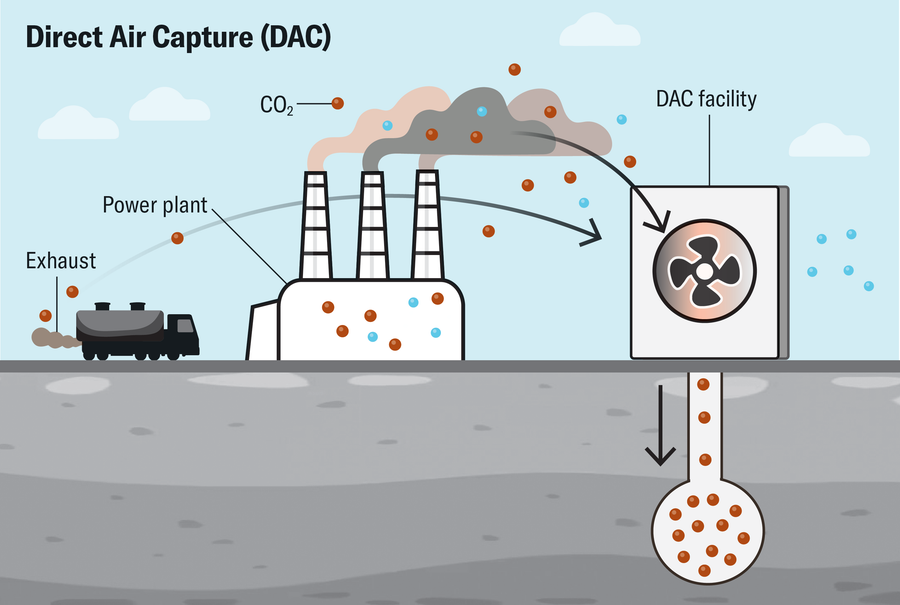

Several years later Lackner co-founded a company called Global Research Technologies, and in 2007 it staged the first demonstration of a technology to extract CO2 from the ambient air, an approach now called direct air capture (DAC). The device was a tall plexiglass box containing plastic sheets that had been coated with a dry CO2-absorbing resin. The box door opened like a wardrobe’s to let air flow across the plastic. When the door shut, the sheets were misted with water, releasing the CO2, which was captured in a tank to be used in industry or stashed away underground. That same year Virgin Atlantic airline owner Richard Branson announced a $25-million prize for a “commercially viable” technology to remove greenhouse gases from the atmosphere.

On supporting science journalism

If you’re enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

Although the chemistry may not be “all that hard,” DAC requires a lot of equipment and a lot of energy—and therefore a lot of money. After the 2008 financial crisis hit, Global Research Technologies ran out of funding. Branson never awarded his prize; a spokesperson said in 2010 that none of the 2,500 entries were ready to draw down any significant quantity of CO2, and he also acknowledgeda growing public “unease” about messing with the atmosphere. Although a few start-ups continued developing their technologies and opened small facilities, notably Climeworks in Switzerland and Carbon Engineering in Canada, DAC fell out of the spotlight.

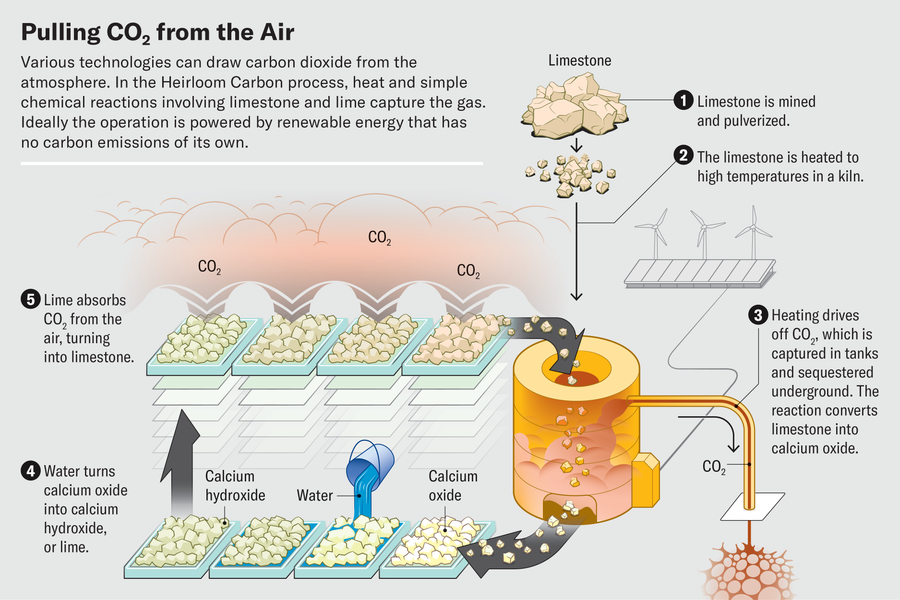

Limestone is the key ingredient in Heirloom’s direct-air-capture process.

Since the 2000s global emissions have only continued to rise, however, and Earth has gotten hotter. Scientists increasingly recognize that limiting warming to the Paris Climate Agreement goal of 1.5 degrees Celsius above preindustrial temperatures will require more than drastically cutting emissions—it will involve pulling hundreds of billions of tons of CO2 out of the atmosphere this century. The most obvious way is planting trees. But even a trillion trees would not be nearly enough, and trees can burn or die of disease, emitting the carbon they’ve stored. In the 2000s the world wasn’t ready for DAC, Lackner says. “Now I think we are too late to do without it.”

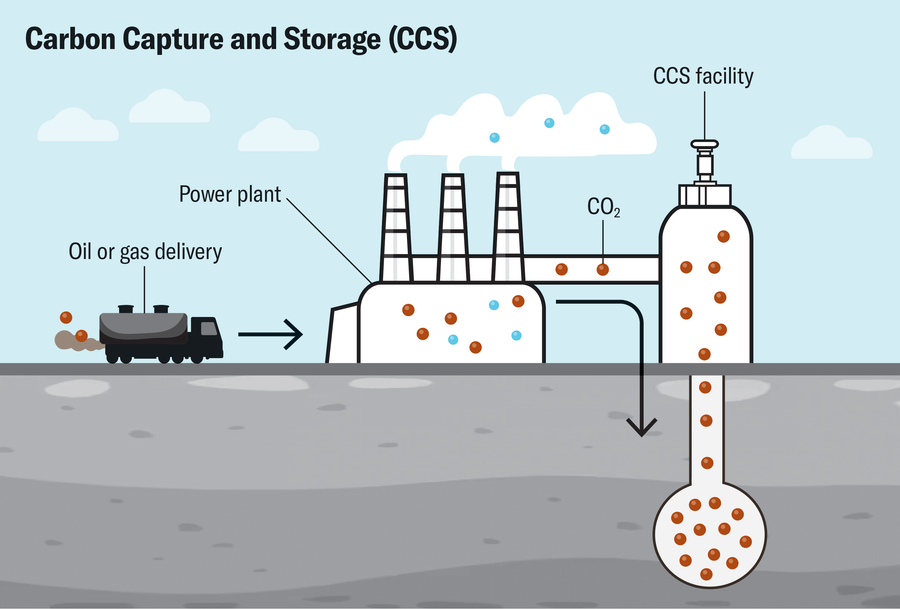

For its goal of reaching net-zero emissions by 2050, the Biden administration is trying to slash carbon pollution by building renewables, electrifying everything from cars to home heating, and encouraging carbon capture and sequestration at power plants. But emissions that are difficult to eliminate, such as those from long-distance air travel, shipping, agriculture, and cement and steel production, will probably have to be removed from the atmosphere, so the government is trying to ramp up DAC. Humans built machines that made a mess; now we’ll build more machines to clean it up. And if the world could start taking more emissions out than it’s putting in—so-called negative emissions—carbon removal could even begin lowering the global temperature slightly.

The U.S. plans to draw down and store more than a billion tons of CO2 annually by 2050, more than one fifth of what it currently emits. For that to be possible, carbon removal would have to become one of the world’s largest industries in just a few decades, expanding by more than 40 percent each year. That’s far faster than most technologies develop—although it is comparable to the pace of solar panels and electric vehicles. “It’d be one of the biggest things humans have ever done,” says Gregory F. Nemet, a professor of public policy at the University of Wisconsin–Madison, who wrote a book called How Solar Energy Became Cheap. “One of the hardest things we’ve ever done. But not unprecedented.”

Key climate laws in 2021 and 2022 included a major tax break for DAC and $3.5 billion in funding to build several regional DAC hubs. Meanwhile, big companies started looking to purchase carbon removal credits to offset their carbon footprint. A business can buy a credit for one metric ton of CO2 that a DAC firm sequestered instead of reducing its own emissions by that amount. To this end, more than 130 commercial DAC plants have been proposed in the U.S. Almost all those plants, however, are planned by an oil company that injects CO2 underground to squeeze out more crude oil from old deposits. U.S. Secretary of Energy Jennifer Granholm has described DAC as “giant vacuums that can suck decades of old carbon pollution straight out of the sky.” But now the question is, Could it also end up putting new carbon pollution into the atmosphere?

Earlier this year I drove an hour east of San Francisco to visit America’s first commercial DAC plant, which Silicon Valley start-up Heirloom Carbon had inaugurated with Secretary Granholm in the farm fields outside Tracy, Calif. After I listened to a safety briefing and put on a hard hat, Heirloom CEO Shashank Samala, a trim, bearded man with a quick grin, took me behind the white mesh netting that surrounded the heart of the plant.

Inside, the operation resembled an oversized industrial kitchen. Hundreds of plastic trays holding what looked like white flour were stacked in 12-meter towers. Rectangular robots moved up and down vertical girders between the towers, checking the flour, which was actually pulverized lime. The lime absorbs CO2 from air passing over the tray, forming calcium carbonate—limestone powder—over the course of about three days. Then a larger, wheeled robot with a forklift pulls trays from the bottom of a stack and dumps the powder into a duct leading to a 900-degree-C kiln outside. When heated, the limestone releases CO2 and turns back into lime. The CO2 is compressed and pumped into a big tank. Later it will be injected underground or mixed into wet concrete, locking the carbon away for centuries. The lime goes back onto the trays to soak up more CO2.

Samala grew up in an 18-square-meter house in Hyderabad, India, where his mother hung a wet towel over a fan to try to keep the family cool during heat waves. His father worked in the U.S. at a Dippin’ Dots ice cream stand and then a pharmacy, and he brought the family to Maine when Samala was 12. After studying economics and robotics at Cornell University and working at the payment company Square, Samala co-founded a company in San Francisco in 2013 that built and delivered custom circuit boards within days.

But Samala was growing concerned about climate disasters, including in India. The 2018 report by the Intergovernmental Panel on Climate Change (IPCC), which for the first time said carbon removal would probably be required to keep global warming to 1.5 degrees C, convinced him that “there is no future of the planet” without the technology. Two years later he founded Heirloom with Noah McQueen, a chemical engineering Ph.D. student. They developed an approach they could scale up to hundreds of plants, ditching the chemical solvents, intricate filters and high-powered fans of other DAC start-ups in favor of cheap limestone and gentle airflow.

Around the same time, big tech firms were starting to invest in carbon removal, sometimes with the goal of offsetting their own considerable emissions. Within months after Heirloom announced its technology on paper, online retail-services companies Stripe and Shopify committed to pay it hundreds of thousands of dollars for future CO2 credits, their own effort to help kick-start the demand for carbon removal. The next year Heirloom raised $53 million from a group of investors that included Bill Gates’s Breakthrough Energy Ventures, and it won a $1-million preliminary award in Elon Musk’s $100-million XPRIZE competition to remove 1,000 metric tons of CO2 a year and “show a pathway” to billions more. The start-up began building the Tracy facility. In August 2023 the U.S. Department of Energy awarded Heirloom and Climeworks—which operates the world’s only other CO2-sequestering commercial DAC facility, on a mountain plateau in Iceland—up to $600 million to build a DAC hub in western Louisiana, along with project manager Battelle. Called Project Cypress, the joint hub is meant to capture a million metric tons of CO2 a year and inject it underground.

The goal of both the DOE and tech firms, several of which have now pooled $1 billion to invest in carbon removal, is to bring down the price of DAC by bringing up capacity. Right now a credit for removing a metric ton of CO2 via DAC costs around $1,000, many times more than the equivalent tree planting. But economies of scale can reduce that, according to Samala. “This will come down the cost curve very quickly,” he said over the whine of compressors and the cymbal-like crash of a vacuum pump. “You’re just putting rocks on trays.”

After California I went to the future site of Project Cypress at Gray Ranch, 400 square kilometers of marshy rangeland on the Louisiana coast, just across the state line from Texas. Driving from Houston to Lake Charles, La., I passed Spindletop Hill, where a 60-meter gusher kicked off the Texas oil boom in 1901. About half of Gray Ranch’s income still comes from leasing land for timber, ranching and oil extraction, says family scion Gray Stream, a wiry, blond man who was waiting for me at his colonnaded historic mansion in boots, jeans, a monogrammed blue shirt and a big pelican belt buckle. But he hopes that carbon sequestration will be its next big business, starting with Project Cypress.

I climbed into a black Cadillac Escalade with Stream and four employees for the 50-kilometer drive to the site. We got out on a gravel road next to a grassy field, with an oil well not far in the distance. As we talked, mosquitoes and turkey vultures began to circle. Within three years this spot will look more like a science-fiction movie set than a cow pasture. Climeworks’s latest technology is a cube 23 meters on edge with mesh sides, rounded corners and 16 fan nozzles sticking out of the top, lifted off the ground by massive concrete feet. Some 60 cubes will stand in rows, connected by compressors and pipes. Inside each cube 16 vented boxes will contain filters coated with an ammonia-derived sorbent, which will capture CO2 from air pulled through the mesh walls by the fans. When the boxes are closed and filled with 100-degree steam, the CO2 will be released into pipes for sequestration. From the pasture the captured CO2 will be pumped about 11 kilometers to another part of the ranch, where Stream’s team will inject it deep underground. Heirloom was going to build a plant here next to Climeworks, but after I visited, it moved its part of Project Cypress north to be near another facility it is developing in Shreveport, La., which will sequester CO2 under a timber plantation in central Louisiana.

We got back in the Escalade to drive to the sequestration site, keeping an eye out for alligators. After 20 minutes we arrived at another grassy field between a barge canal and a derelict windmill. Stream got the idea to inject carbon here in 2018, after nongovernmental organizations, energy companies and senators from fossil-fuel states banded together to more than double a tax break known as 45Q. That allowed companies such as the Gulf Coast’s natural gas and petrochemical producers to receive a tax credit of up to $50 for every metric ton of CO2 they captured with scrubbers on their smokestacks and sequestered underground, a process known as carbon capture and sequestration. In 2022 a coalition including Senator Joe Manchin of West Virginia, the senate’s top recipient of oil and gas donations, helped increase 45Q to $85 per metric ton of CO2 captured from a smokestack and $180 per metric ton captured via DAC. For each metric ton they remove in Project Cypress, Climeworks and Heirloom can claim that tax credit while also selling a carbon credit to customers who want to offset their emissions—all while the DOE matches up to $600 million of their investment in the project. To sequester the CO2, Climeworks will pay Stream, whose ranch sits over a “birthday cake” of rock layers perfect for trapping it underground. “The geology is the magic,” Stream says.

Fans behind a mesh wall pull air into the carbon-capture operation when winds are light or stagnant.

That geology began to form 65 million years ago, when the Rocky Mountains surged upward and rivers such as the young Mississippi began to carry grains of crushed sand downhill to the Gulf of Mexico. Through the eons new layers of sediment piled on, and under their weight the older ones below were compressed into porous sandstone. Now and then sea levels would rise, depositing a muddy layer that became shale rock. In places like Gray Ranch, a shale layer forms a dome of impermeable “cap rock” that can seal off CO2 injected through a well into the sandstone pores below. This layering makes the Gulf Coast the “Saudi Arabia of pore space,” Stream says, with room for an estimated 100 billion metric tons of CO2.

If Louisiana approves Stream’s well permit, his team will drill down 2,750 meters through the shale and start injecting compressed CO2 into the sandstone below. Geologists will watch with instrumentation as the plume of superdense CO2 displaces salt water from the pores and migrates upward into the shale dome, monitoring it to see whether it stays trapped. They plan to inject 100 million metric tons of compressed CO2 at three sites over 30 years. But modeling the subsurface can be difficult. At a carbon-sequestration project in the North Sea, the plume broke through eight thin shale layers before being trapped by a previously undiscovered ninth layer. There are also 120,000 abandoned oil wells in Louisiana that CO2 could potentially escape through, although Stream says the half a dozen wells near his sequestration site have been properly plugged.

Residents in predominantly Black Lake Charles are concerned, however, about the possibility of a rupture in a pipeline transporting CO2 to the site. A leak in a multistate network of CO2 pipelines put 45 people in neighboring Mississippi in the hospital in 2020, and another one in a Lake Charles suburb forced officials to issue a shelter-in-place order this past April. More broadly, they’re worried that Project Cypress will help perpetuate a legacy of environmental racism. Every night the area glows orange with the flares of more than two dozen fossil-fuel and petrochemical facilities. Driving back to Stream’s lakeside home, we passed the Westlake chemical complex, where a 2022 explosion injured six workers. A chlorine plant next door burned down after Hurricane Laura struck in 2020. Two other plants have been caught leaking ethylene oxide and benzene, chemicals that can cause cancers such as leukemia.

The DAC hubs are required to benefit local communities. But Roishetta Sibley Ozane, a Black environmental justice activist whose children have suffered from asthma and epilepsy possibly linked to pollution, says the DOE consulted Lake Charles residents only after it had already chosen them as “guinea pigs” for an unproven technology. The CO2 sequestration at Gray Ranch will attract even more gas and petrochemical plants, she fears, because Stream plans to also inject CO2 captured by scrubbers at industrial facilities. At least a dozen fuel plants with scrubbers have been proposed in Louisiana. “I don’t have the answers,” Ozane says. “We have to stop what’s happening right now—and that does not look like putting a giant DAC hub in the communities that are already overburdened with industry.”

Robots deliver trays that have soaked up CO2 to a kiln that bakes out and collects the gas.

DAC still has to answer the question of who will pay. The DOE estimates that by the time the industry is removing a billion metric tons of carbon from the atmosphere every year, the cost of each ton will fall below $100, which will make it profitable based on the 45Q tax credit alone. An April study by researchers at ETH Zurich, however, projected that DAC would still cost about $360 per metric ton. At that rate the cost to suck up a billion metric tons could be more than 1 percent of the U.S. gross domestic product. And it’s hard to imagine even cash-flush tech firms voluntarily spending hundreds of billions of dollars on credits every year. The U.S. government—or at least numerous individual states—will probably have to somehow limit companies’ emissions, Nemet says, and force polluters to pay to remove CO2. California has started: companies that want to sell gasoline and diesel in the state have to either reduce their emissions or buy credits. If approved, Climeworks and Heirloom could sell some of those credits to them.

Alongside equipment, energy is the main cost. The million-metric-ton Project Cypress will consume as much electricity as 230,000 U.S. homes. Removing a billion metric tons would require up to twice the electricity the U.S. generated via renewables in 2023. Even without that extra demand, the U.S. isn’t on course to meet its renewable-energy goals. Critics have argued that investments in DAC would be better spent on replacing natural gas and coal power, which still generate most U.S. electricity. Running a DAC plant with wind power would put up to 42 percent more CO2 in the atmosphere over two decades than replacing a coal plant with that same wind power, according to a 2019 study by Mark Z. Jacobson, a civil and environmental engineering professor at Stanford University. And it wouldn’t reduce coal pollutants such as sulfur dioxide. “Until every fossil plant and every bioenergy plant is gone, there’s no benefit whatsoever of direct air capture,” Jacobson says. “It always increases air pollution, increases CO2, increases fuel mining, increases fossil infrastructure.”

There are also concerns that DAC poses a “moral hazard” for the steep reduction in fossil-fuel use that scientists say is necessary: Why stop burning carbon if you think you can just suck it out of the air later? The world is way behind in meeting the 1.5-degree-C goal, yet major oil and gas countries, including the U.S., are set to increase production through 2050. “The reliance on these future speculative techno fixes delays real climate action right now,” says Lili Fuhr, an analyst at the Center for International Environmental Law. In fact, the biggest private investor in DAC is the major U.S. oil company Occidental Petroleum, or Oxy, whose CEO has said the technology means “there’s no reason not to produce oil and gas forever.”

Granular lime on the trays turns into limestone in about three days as it reacts with CO2 in the air.

After Gray Ranch, I drove south along the coast to Corpus Christi, Tex., a mostly Latino city that was once known for its beaches but has become America’s biggest oil-exporting port. In addition to Project Cypress, the DOE awarded up to $600 million to a DAC hub being developed here by Oxy. Climeworks and Heirloom have said DAC shouldn’t be a reason to expand fossil fuels, but for Oxy it’s part of a strategy to sell “net-zero oil.” The idea is that emissions from burning newly produced oil would be offset by CO2 captured by Oxy’s DAC operations. Oxy is already building a separate, 500,000-metric-ton DAC plant in West Texas called Stratos and will inject some of the CO2 it captures there into old oil wells to force out more crude, a practice known as enhanced oil recovery (EOR). Last year Oxy’s CEO, Vicki Hollub, said DAC “gives our industry a license to continue to operate for the 60, 70, 80 years that I think it’s going to be very much needed.”

Fifteen kilometers south of Corpus Christi, past a megachurch, a fireworks store and some Quonset huts, the gravel road came to a “no trespassing” sign. A dozen wind turbines rumbled in the sea breeze. Beyond a line of scrubby mesquite lay King Ranch, an estate larger than Rhode Island that inspired the oil-boom film Giant starring James Dean. As soon as next year, Oxy’s South Texas DAC Hub will rise from these umber fields. Oxy declined to comment or let me visit the site, but online renderings suggest it will be a set of long buildings with perforated black walls and a line of huge, round fans in their metal roofs. The fans will suck air through the permeable walls, where potassium hydroxide flowing across honeycombed plastic sheets will bond with CO2 to form a solution of potassium carbonate. Combining that with calcium hydroxide in a “pellet reactor” will generate limestone pellets, which can be heated in a kiln to release CO2 into rows of tanks behind the buildings.

The hub’s development has so far been shrouded in secrecy. On a minibus tour of the historic central part of King Ranch, 40 kilometers to the west in Kingsville, Tex., our guide talked for an hour and a half about its famous racehorses and squat orange cattle. But she redirected my questions about the DAC hub to management, which never replied to my numerous calls and e-mails. The King Ranch Museum archivist said she can’t talk without permission. The president of the local chamber of commerce said he had signed a nondisclosure agreement. The county judge, who lobbied for the hub, agreed to an interview with me on two occasions but canceled both times. “I don’t know if we’re allowed to talk about it,” said a worker who was clearing brush near the ranch entrance.

Oxy’s Hollub is a villain or a visionary, depending on whom you ask. The Alabama native worked her way up from oil rig engineer, and in 2016 she became the first female CEO of a major U.S. oil company. She started developing Stratos after the U.S. increased the 45Q tax credit two years later. That’s partly because Oxy had become the biggest EOR producer in Texas. During EOR, compressed CO2 displaces oil that’s stuck in rock pores, boosting yields by up to 25 percent. Most of the CO2 is sequestered in the deposit, but consumers eventually burn the oil produced, creating more emissions. Oxy, which obtains CO2 mined from natural reservoirs, was searching for other sources.

By obtaining CO2 via DAC, Hollub realized, the company could have a triple win: take the tax credit, sell carbon credits and produce more oil. After Hollub helped to successfully lobby Congress to raise the credit to $130 per metric ton for DAC plus EOR, she announced Oxy would open 130 DAC plants by 2035. When the DOE selected its South Texas DAC Hub, Oxy bought Canadian DAC technology firm Carbon Engineering for $1.1 billion. It now has an agreement to offer net-zero oil to a South Korean refiner and has sold carbon credits that will not be linked to EOR to companies including Microsoft, Airbus and Amazon.

The Heirloom direct air-capture plant could extract 1,000 tons of CO2 a year. One thousand such plants could remove a million tons, a small start at counteracting the ongoing rise of CO2 emissions.

Chevron and Shell are investing in both oil drilling and DAC, and they have received smaller grants to pursue their own DAC hubs. The DOE says this funding can help scale up the technology for everyone’s benefit while shifting the companies away from fossil fuels. “It’s giving them an opportunity to pivot,” Jennifer Wilcox told me in March, when she was the deputy head of the DOE’s Office of Fossil Energy and Carbon Management (she has since left the DOE). “And these are the companies that have the resources and the assets to actually do it.”

But Emily Grubert, a University of Notre Dame sociologist who previously worked for the DOE on DAC hubs, says “paying the oil companies to stop doing oil” is fruitless. She and others argue that the carbon-removal industry should be nationalized, with the government limiting emissions and paying for capture, akin to municipal garbage collection for the atmosphere. Activists such as Ozane have called for the hubs to be at least partially owned by communities. Unregulated, for-profit DAC is “going to be captured by the fossil industry,” Grubert says.

At the ribbon cutting for Heirloom’s Tracy plant, Samala compared DAC to a time machine that could take us back to an earlier, less screwed-up climate. But for now the DAC time machine is “next to useless,” University of Hawaii oceanographer David Ho wrote in Nature last year: with humanity emitting 40 billion metric tons of CO2 a year, the million removed annually by each DAC hub would take us back in time only 13 minutes.

But let’s say the nations of the world cut carbon emissions 90 percent by 2050. Several thousand DAC plants running on excess renewable energy could then draw down the final 10 percent to reach net zero. In that scenario, global temperatures would probably peak at 1.6 degrees C above preindustrial levels, according to IPCC modeling.

If we went on to build vast amounts of additional DAC capacity, we could start to turn back the clock on climate change. Taking 220 billion metric tons of CO2 out of the atmosphere by 2100 would bring temperatures down to about 1.3 degrees C above preindustrial levels, only slightly hotter than today. Deadly catastrophes such as the heat waves in the U.S., the drought in the Amazon, and flooding in Afghanistan and Pakistan this year would continue to happen. But they would happen about half as often as with the 2.9 degrees C of warming we’re headed for currently. Done right, carbon removal could also become an instrument for environmental justice, lessening future disasters caused mostly by emissions of the rich and hurting mostly the poor and vulnerable.

For us to have even a shot at that future, we would need to ramp up DAC investment now, Ho says. “If we’re leaving future generations all the cumulative emissions in the atmosphere,” he says, “it’s almost our responsibility to give them a tool to remove it.”